Minimise Downtime By Choosing Quality Bearings From BTL-UK

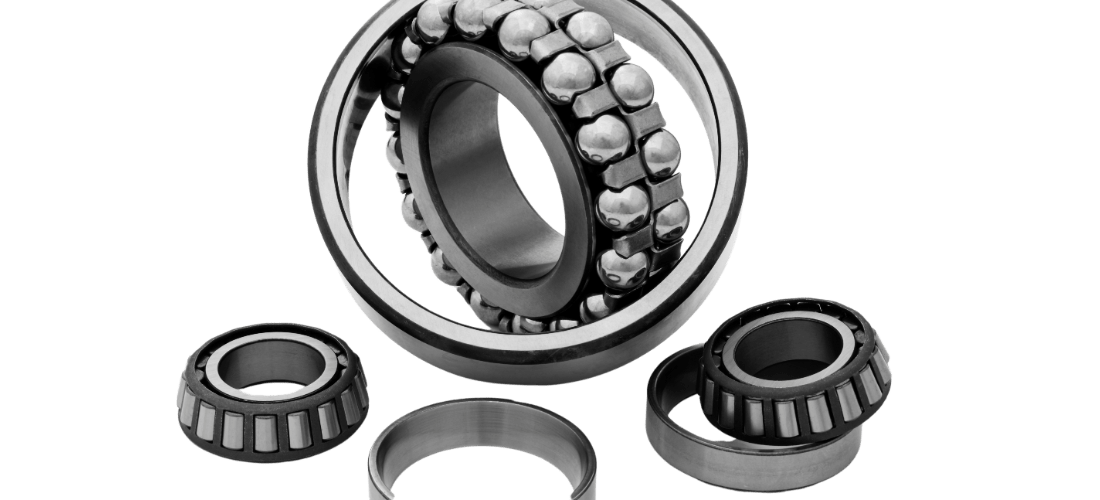

Ball and roller bearings play a crucial role on production lines, enabling smooth rotation and movement in complex machinery. As a vital component in a range of industrial equipment, bearings enhance efficiency, reduce wear and tear, and extend the lifespan of critical industrial components. So, when a bearing unexpectedly fails, unplanned downtime is inevitable while repairs are undertaken, resulting in damaged productivity, delayed orders, and lost income.

In this article, we’ll explore how the best quality bearings can make a significant impact on the efficiency and productivity of your production line and why you should invest in roller bearings from BTL-UK.

The Threat Posed By Contamination

Dirt is a persistent problem in many industries and can wreak havoc on the performance of your machinery. As one of the most critical components of any rotating machine, bearings are particularly vulnerable to the infiltration of dirt. While low-quality bearings simply cannot perform effectively if equipment becomes contaminated, BTL-UK's bearings are designed and sealed against dirt, keeping contamination out and ensuring that your bearings keep spinning smoothly. By choosing high-quality bearings from BTL-UK, you will take a proactive step in protecting your equipment from damage and extending its operational life.

Heavy Loads Demand Robust Bearings

Heavy loads are commonplace in industrial settings, so bearings must be able to withstand extreme weight without suffering damage. From conveyor belts carrying tonnes of material to the massive gears of construction cranes, heavy loads can put immense strain on bearings. A bearing that is not designed to handle excessive loads is a weak link in your production line and is likely to deliver poor performance or fail prematurely, resulting in disruptive downtime. At BTL-UK, our ball and roller bearings are engineered to cope with the heaviest loads, making them a reliable choice for industries where durability is non-negotiable.

Preventing A Domino Effect

In industrial settings, the failure of one component can quickly set off a chain reaction, leading to more widespread problems and downtime. When a single bearing fails, for example, it can lead to the damage of adjacent bearings and other vital components, which results in costly repairs and extended downtime. By choosing high-quality bearings from BTL-UK, you're investing in the reliability of your machinery. BTL-UK's bearings are built to perform under pressure, reducing the risk of failures that can cascade throughout your equipment.

Safeguarding The Wellbeing Of Your Team

As well as the considerable financial implications of faulty bearings, their failure can also pose a significant safety risk to site staff. A malfunctioning bearing can lead to accidents and injuries, which not only halts production but also raise serious health and safety concerns. Choosing quality bearings from BTL-UK is not just an investment in your equipment but also in the wellbeing of your workforce.

Find Out More

Investing in high-quality bearings suitable for a heavy radial load is one of the most cost-efficient and effective steps you can take to overcome the problem of manufacturing downtime. For more information, please download our free guide ‘The Manufacturer’s Guide to Overcoming Distribution Problems’ or call BTL-UK on 01233 542267.

Image Source: Canva