Why Quality Bearings Are Essential For Agricultural Machinery

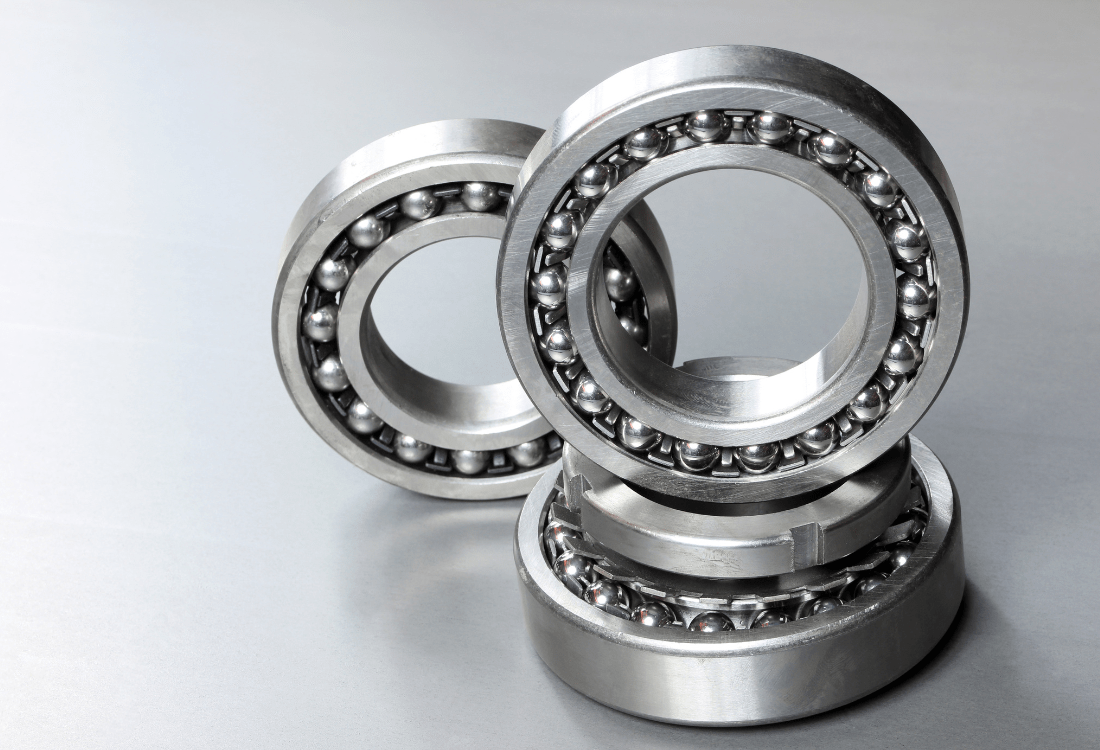

Precision engineering forms the foundation of modern agricultural machinery. From seed drills and fertiliser applicators to combine harvesters and tractors, innovative technology allows farmers to work faster, smarter, and more sustainably. However, none of this would be possible without high-performance bearings inside these complex machines.

The Importance Of Smooth, Precise Movement

By incorporating high-quality bearings, OEM engineering designers can prioritise both safety and longevity in agricultural machinery, minimising the risk of component failures. Superior bearings enable the moving parts inside farming equipment to operate smoothly and precisely. This includes rotating shafts, gears, pulleys, and more.

Smooth rotation prevents excessive vibration, noise, and heat build-up. This saves energy and minimises wear and tear on adjacent components. Precision movement also ensures accurate seed dispersal, fertiliser application, and efficient crop collection. If bearings fail, farming processes suffer costly disruptions.

Withstanding Harsh Conditions

Agricultural machinery operates outdoors, enduring extreme weather, muddy landscapes, and rugged terrain on a daily basis. Quality bearings are designed to cater for such harsh conditions, safeguarding precision functionality.

They can handle extreme temperatures, vibrations, and pressure, ensuring reliable operation and minimising the risk of breakdowns or component failures. Special seals prevent external contamination while retaining lubrication inside the bearings.

After all, agricultural machinery cannot afford extended downtime during critical harvesting windows. By keeping bearings in prime condition, farmers avoid missing those small sowing or growth opportunities that tangibly impact annual yields and profits.

Lower Maintenance Requirements

Many agricultural machines incorporate universal catalogue bearings into their designs. While sufficient for basic loads, general-purpose models often sacrifice performance and durability compared to premium alternatives. Quality bearings built explicitly for farming applications offer vastly improved lifespans.

Superior quality bearings require less frequent replacement, leading to reduced maintenance costs and downtime for repairs. Their advanced sealing systems also retain lubrication much longer than standard models, minimising servicing needs. This enables farmers to spend less on spares and repairs while maximising productivity.

Facilitating Innovative Designs

Beyond incremental improvements, high-end bearings empower manufacturers to deliver revolutionary designs with enhanced capabilities. For instance, quality bearings support higher rotational speeds empowering new generations of ultra-efficient farming equipment.

They also withstand greater loads which facilitates larger machine capacities and productivity. Even entirely new automated, AI-enabled agricultural robots rely on superb bearings to enable precise positioning and responsive actuation.

By removing mechanical constraints, speciality catalogue bearings facilitate cleaner, leaner, and more sustainable farming practices through cutting-edge automation.

Learn Everything You Need to Know About Bearings with BTL

Overlooking bearing quality jeopardises agricultural output. Subpar bearings lead to increased downtime, more frequent part replacements, and unnecessary manufacturing expenses. They also introduce safety hazards while limiting abilities.

Instead, investing in proven, high-grade bearings tailored for farming machinery optimises performance, efficiency, and innovation. By serving reliably for years even in harsh conditions, quality bearings deliver outstanding returns on investment across the board. To learn more, download BTL's Ultimate Guide To Bearings, Mechanical Power Transmissions And Linkages or Get in touch.

Image Source: Canva