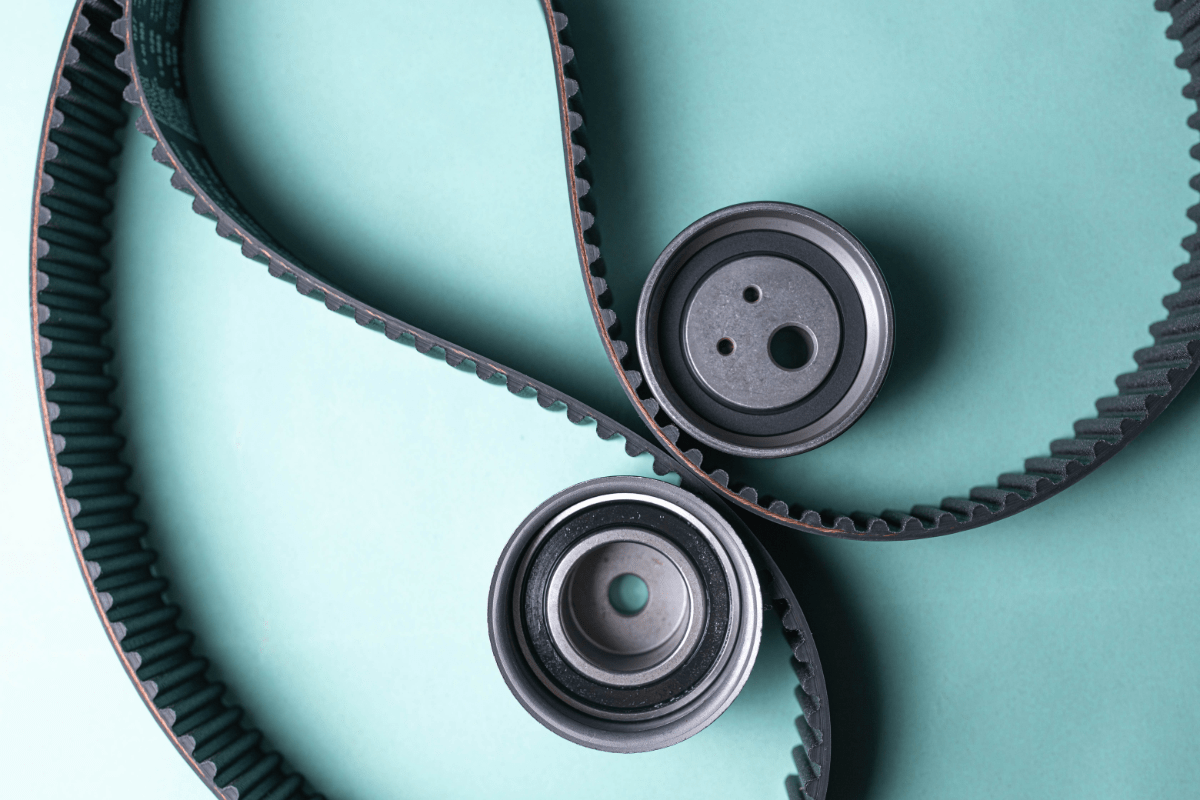

Is An Idler Pulley And Tensioner Pulley The Same?

Idler pulleys and tensioner pulleys are similar components in that both types of pulley are used in belt driven systems – in which they play complementary and supporting roles. But they are not the same and both types of pulley serve different purposes within mechanical systems. The main physical difference between an idler pulley and tensioner pulley is a simple adjustable bolt! However, in terms of function and purpose, an idler pulley is responsible for guiding a belt drive in an engine or mechanical system, while a tensioner pulley is responsible for tensioning the drive belt.

The main physical difference between an idler pulley and tensioner pulley is a simple adjustable bolt! However, in terms of function and purpose, an idler pulley is responsible for guiding a belt drive in an engine or mechanical system, while a tensioner pulley is responsible for tensioning the drive belt.

The engine belt or chain loops under or around the idler pulley, creating a continuous loop that allows the belt to move freely. The tensioner pulley helps keep the chain or belt tight, so that it can transfer motion and power efficiently from the crankshaft to other components in the system.

Let’s look at the differences and uses in some more detail

Idler Pulley

An idler pulley is a wheel or bearing used to guide a belt or chain efficiently around a specific path, and does not provide tension to the belt. The pulley helps maintain proper alignment within the system and reduces the amount of wear and tear on the belt or chain – and subsequently on the system itself. Idler pulleys are manufactured from various metals, including hardened steel, stainless steel, or aluminium, as well as rubber or plastic – and are available in various shapes and sizes depending on the application.

Tensioner Pulley

A tensioner pulley is another type of bearing or wheel that applies tension to a belt or chain, helping keep the belt taught and preventing it from slipping or jumping off of other components. The tensioner pulley is located at one end of the belt and works by transferring the force from a hydraulic piston or spring and applying it to the system, keeping the belt/chain tight and avoiding components coming loose and causing damage to the system. Like idler pulleys, tensioner pulleys are available in several metal and polymer materials and can be manufactured in various sizes and shapes – steel is the most common material of choice for high performance applications, due to its durability and low coefficient of friction, which helps reduce wear and tear on the belt circuit.

Belts And Pulleys From BTL-UK

At BTL-UK, we stock a wide range of belts, pulleys, and power transmission components for mechanical systems, including automotive engines, construction plant, conveyor systems, and machinery. Please get in touch or even feel free to call one of our experienced team on 01233 542780 for personalised advice about the best components to use in your application.

Image Source: Canva